产品介绍:

天然气疏水阀

TSS43H系列天然气疏水阀是一种全自动排液装置,该产品在不使用其它动力的条件下使天然气矿的气水分离器或天然气储罐中的沉积水(液)实现全自动排放,排放水(液)的过程中无天然气泄漏,避免了人工排工(液)带来的天然气损失(约为产量的1%),对确保供气质量、净化环境、实行清洁生产、消除安全隐患和改善劳动条件均具有显著的作用。

Natural gas trap valve

TSS43H series natural gas trap valve is a fully automatic liquid discharge device, the product that sedimentary water gas water separator or gas tank gas in power without the use of other conditions (liquid) to achieve automatic discharge, waste water (liquid) without gas leakage in the process of avoiding artificial schedule (liquid) caused by natural gas losses (about 1% of production), to ensure supply of quality, purifying the environment, the implementation of cleaner production, eliminate safety hazards and improving working conditions have a remarkable effect.

功能特点:

1、 全天候全自动连续作业,有水就排,无水自动关闭,沉积水(液)排放率100%。

2、 阻气严密,运行中无天然气泄漏,漏气率为零。

3、 自动沉降污物,实行定期排污。

4、 内件材料为全不锈钢,阀体内避经防腐处理,使用寿命长。

5、 安装方便,无需调试,运行平稳,安全可靠。

functional features:

1、all-weather automatic continuous operation, there is water on the row, no water automatic shutdown, sink water (liquid) discharge rate of 100%.

2、gas tight, no gas leakage in operation, the leakage rate is zero.

3、automatic settlement of dirt, the implementation of regular sewage.

4、the internal material for all stainless steel, inside the valve to avoid corrosion treatment, long service life.

5、easy installation, no debugging, smooth operation, safe and reliable.

技术特性Technical characteristics:

|

型号 Model |

公称通径 Nominal diameter (mm) |

公称压力 Nominal Pressure (MPa) |

工作压力 Working Pressure (MPa) |

工作温度 working Temperature (℃) |

排水量 Displacement (M3/h) |

漏气率 Leak rate (%) |

排水率 Drainage rate (%) |

|

TSS43H-16 |

25 32 40 50 65 80 100 150 |

1.6 |

≤1.6 |

常温 Ambient temperature |

2-50 |

0 |

100 |

|

TSS43H-25 |

2.5 |

≤2.0 |

|||||

|

TSS43H-40 |

4.0 |

≤3.0 |

|||||

|

TSS43H-63 |

6.3 |

≤5.0 |

|||||

|

TSS43H-100 |

10.0 |

≤8.0 |

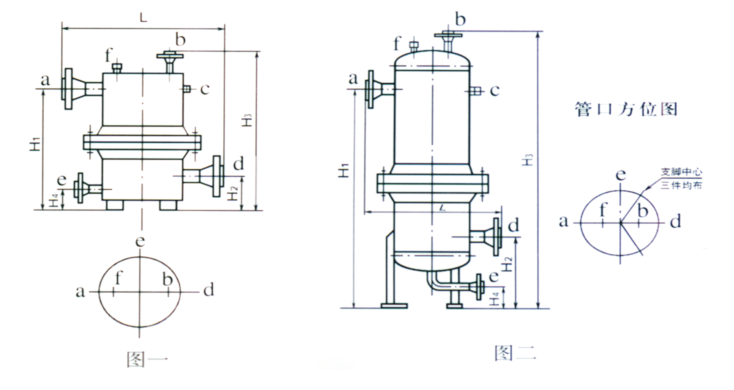

外形简图: a、进水口 b、回气口 c、检查口 d、排水口 e、排污口 f、备用口M20×1.5螺塞

Outline drawing: a、Intake b、Air return port c、Inspection Gate d、Outfall e、sewage outfalls f、Reserve portM20×1.5Plug

型号、规格、工作参数年、安装尺寸:

TSS43H天然疏水阀按可疏液体中成份的不同分为A系列和B系列两种。

A系列表示可疏液体是水,无其它液体成份(表一)。

B系列表示可疏液体为油或水和凝析油的混合液体(表二)。

如果天然气中含有H2S气体,应选用抗硫型天然气疏水阀,抗硫天然气疏水阀的型号是普通型天然气疏水阀型号前加“k”。表中()内的型号即为相应型号的抗硫型疏水阀。

model, specification, work parameter year, installation size:

TSS43H natural trap according to the liquid can be divided into different components of A series and B series of two.

The A series means that the liquid is water free and has no other liquid components (Table 1).

The B series represents a mixture of liquids that can be dispersed as oil or water and condensate (table two).

If natural gas contains H2S gas, sulfur resistant natural gas traps shall be selected. The type of sulfur resistant natural gas trap is common type of natural gas trap, plus "K"". The model in the table is the anti sulfur trap of the corresponding model.

A系列series 表 一 (Table 1)

|

型号 Model |

规格号 Specif ication number |

公称压力 Nominal pressure (MPa) |

工作参数 Working parameter |

安装尺寸 Installation size |

进口出口Imported Exit |

综合说明 Comprehen sive Descr iption |

||||||

|

工作 压力 上限 Working ressure (MPa) |

排水量 Displacement (M3/h) |

H1 mm |

H2 mm |

H3 mm |

L mm |

图示 Icon |

DN mm |

PN MPa |

||||

|

TSS43H-16 (KTSS43H-16) |

A1 |

1.6 |

0.8 |

2 |

500 |

200 |

680 |

540 |

图一 |

40

50

65

80

100 |

1.6 |

1、排污口 尺寸: 所有规格 号均为 DN40, PN同进口 H4=100mm; 2、回气口 连接 尺寸: 所有规格 号均为DN15, PN同进口。 3、 法兰 标准: 当PN≤ 2.5MPa时 为:JB/T 81-94 当2.5< PN≤10MPa时 为:JB/T 82.2-94A 型

|

|

A2 |

5 |

600 |

200 |

780 |

600 |

|||||||

|

A3 |

10 |

730 |

200 |

910 |

600 |

|||||||

|

A4 |

15 |

850 |

200 |

1030 |

630 |

|||||||

|

A5 |

1.5 |

2 |

500 |

200 |

680 |

540 |

||||||

|

A6 |

5 |

600 |

200 |

780 |

600 |

|||||||

|

A7 |

10 |

730 |

200 |

910 |

600 |

|||||||

|

A8 |

15 |

730 |

200 |

910 |

630 |

|||||||

|

TSS43H-25 (KTSS43H-25)

|

A9 |

2.5 |

2.0 |

2 |

500 |

200 |

680 |

540 |

2.5 |

|||

|

A10 |

5 |

600 |

200 |

780 |

600 |

|||||||

|

A11 |

10 |

860 |

200 |

1040 |

600 |

|||||||

|

A12 |

15 |

880 |

200 |

1060 |

630 |

|||||||

|

TSS43H-40 (KTSS43H-40) |

A13 |

4.0 |

3.0 |

2 |

580 |

200 |

750 |

540 |

4.0 |

|||

|

A14 |

5 |

600 |

200 |

770 |

600 |

|||||||

|

A15 |

10 |

880 |

320 |

1180 |

630 |

图二 |

||||||

|

A16 |

15 |

1000 |

320 |

1320 |

630 |

|||||||

|

TSS43H-63 (KTSS43H-63) |

A17 |

6.3 |

4.5 |

2 |

710 |

200 |

900 |

540 |

图一 |

6.3 |

||

|

A18 |

5 |

730 |

200 |

920 |

600 |

|||||||

|

A19 |

10 |

1000 |

320 |

1320 |

630 |

图二 |

||||||

|

A20 |

15 |

1150 |

320 |

1470 |

630 |

|||||||

|

A21 |

5.5 |

2 |

710 |

200 |

900 |

540 |

图一 |

|||||

|

A22 |

5 |

730 |

200 |

920 |

620 |

|||||||

|

A23 |

10 |

1000 |

320 |

1320 |

630 |

图二 |

||||||

|

TSS43H-100 (KTSS43H-100) |

A24 |

10.0 |

6.0 |

2 |

710 |

200 |

900 |

540 |

图一 |

10.0 |

||

|

A25 |

5 |

730 |

200 |

920 |

620 |

|||||||

|

A26 |

10 |

1120 |

340 |

1140 |

680 |

图二 |

||||||

|

A27 |

8.0 |

2 |

880 |

340 |

1180 |

620 |

||||||

|

A28 |

5 |

1120 |

340 |

1420 |

620 |

|||||||

|

A29 |

10 |

1120 |

340 |

1440 |

680 |

|

||||||

B系列series 表 二 (Table 2)

型 号

Model

规格号

Specif

ication

number

公称

压力

Nominal

pressure

(MPa)

工作参数

Working

parameter

安装尺寸

Installation

size

进口

出口

Imported

Exit

综合说明

Compreh

ensive

description

工作

压力

上限

Working

pressure

(MPa)

排水量

Displacement

(M3/h)

H1

mm

H3

mm

L

mm

图示

Icon

DN

mm

PN

MPa

TSS43H-16

(KTSS43H-16)

B1

1.6

0.8

2

700

200

880

540

图一

40

50

65

80

100

1.6

1、排污口

连接

尺寸:

所有规格

均为

DN40,

PN

同进口,

H4=

100mm;

2、回气口

连接

尺寸:

所有规格

号均为

DN15,

PN同进口。

3、法兰

标准:

当PN≤

2.5MPa时

为:JB/T

81-94

当2.5<

PN≤

10Mpa时

为:JB/T

82.2-94A型

B2

5

730

200

910

600

B3

10

850

200

1030

630

B4

1.5

2

700

200

880

540

B5

5

850

200

1030

600

B6

10

850

200

1030

600

TSS43H-25

(KTSS43H-25)

B7

2.5

2.0

2

700

200

880

540

2.5

B8

5

730

200

910

600

B9

10

1030

320

1350

630

图二

TSS43H-40

(KTSS43H-40)

B10

4.0

3.0

2

600

200

980

600

图一

4.0

B11

5

850

200

1030

600

B12

10

1030

320

1350

630

图二

TSS43H-63

(KTSS43H-63)

B13

6.3

4.5

2

730

200

910

600

图一

6.3

B14

5

1000

320

1320

630

图二

B15

10

1150

320

1450

630

B16

5.5

2

730

200

910

600

图一

B17

5

1030

320

1350

630

图二

TSS43H-100

(KTSS43H-100)

B18

10.0

6.0

2

850

200

1030

620

图一

10.0

B19

3

980

200

1160

620

B20

8.0

2

1150

340

1470

620

图二

B21

3

1150

340

1470

620

安装及维护:

1、该疏水阀应水平安装,在管线路较低位置,阀前应装截止阀,过滤器同时安装旁通阀。

2、本疏水阀安装完毕,开启进口截止阀,再开启出口截止阀,疏水阀开始正常运行排水连续作业。

3、安装方向:阀体上的箭头指向与管道内流体方向一致(箭头指向为流体出口端)。

4、排污清除:由于长期累积随凝结水进入疏水阀腔内,会有一定的渣污。

5、排污操作:关闭疏水阀前与后的截止阀,然后打开底部污球阀,再慢开进口截止阀,以凝结水冲洗本阀内腔渣物,直至冲洗内部干净为止。

6、为了防止渣物进入疏水阀,根据用户各自管道情况,定期进行清除污渣,可使疏水阀保持良好的正常工作。

Installation and maintenance:

1, the valve should be installed horizontally in the pipeline, the lower position, the valve should be installed before the cut-off valve, filter bypass valve installed at the same time.

2, the trap installed, open the inlet stop valve, and then open the outlet valve, the trap began to run normally, drainage continuous operation.

3. Installation direction: the arrow on the valve body is in line with the direction of the fluid in the pipe (arrow pointing to the outlet of the fluid).

4, sewage clearance: as a result of long-term accumulation, with the condensate into the trap cavity, there will be a certain amount of slag.

5, sewage operation: close the trap before and after the cut-off valve, and then open the bottom dirty ball valve, and then slowly open the inlet stop valve, with condensed water to wash the valve cavity slag, until the rinse clean inside.

6, in order to prevent slag into the trap, according to the user's respective pipe conditions, regular cleaning debris, can make trap to maintain good normal work.

中文

中文 English

English