产品介绍:

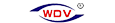

带开口集水罐的凝结水自动泵典型安装

凝结水控制泵把开口集水罐内的冷凝水排入可能有压力的高架冷凝水回液管内。为了安全,如果使用蒸汽驱动时,泵的排气口和集水罐应通大气。

Automatic and typical installation of condensate water collecting tank with opening

Condensate water automatic pump will discharge the condensed water that contained in open water collector into high jump stand condensate water return pipe with possible existence of pressure.For safety,it`s advisable to adopt the exhaust valve and water collector with ventilation whenever using steam driving.

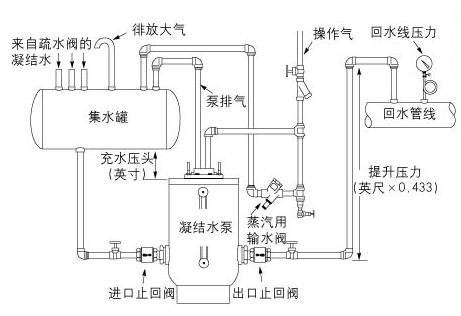

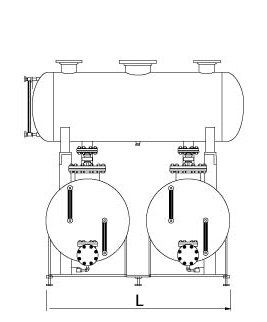

封闭系统凝结水自动泵的典型安装

冷凝水从一个有压系统排入另一较高压力的系统。凝结水自动泵的进口管和回液管可能都是抬高的。这种安装方法用一个带压集水罐也可用于高疏液量工艺装置。

Typical installation of closed system condensate water automatic pump

Condensate water will be discharged from apressure system to another rather high-pressure system.it`s possible that both inlet tube and return pipe are rose,such installation method could be used in the water collector with pressure,also applicable to the equipment with high volume of liquid dispensing.

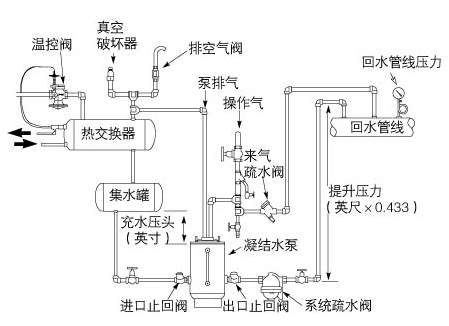

常压集水罐凝结水控制泵安装示意图

A schematic diagram for the installation of the condensate control pump in the atmospheric water tank

基本原理

冷凝水控制泵属于一种压力控制泵,主要设计用于不适用电力来泵送冷凝水或其他流体的场合。与传统的电力疏液泵相比,冷凝水控制泵特别适用“困难”介质的疏液,如高温冷凝水或腐蚀性流体。压力操作的泵,特别是冷凝水控制泵被公认为是长寿命,很少维修的泵。这种泵由于没有旋转的密封结构,没有电动机和泵叶轮,通常使用寿命是传统电动泵的五到十倍,同时省去了大部分一般性维修。

1、把高温凝结水送回锅炉,节省锅炉给水化学处理剂,减少制造材料锅炉给水再加热的费用。

2、泵不需要电气维修。

3、泵可安全用于危险的或爆炸性的环境。

4、根据不同的型号,可以用0.5到1.6Mpa表压力的蒸汽、压缩空气或其他气体操作控制。

5、疏液量最大可达22,000Kg/h。

冷凝水控制泵靠蒸汽或压缩气体排出液体。浮球联到连杆上和弹簧上,同时驱动进汽阀和排气阀。在充液循环中,进汽阀关闭,同时排气阀打开,使冷凝水充入泵体内。当浮球随液位升高到其行程的顶点时,开关控制机构放开弹簧,打开进汽阀,关闭排气阀。蒸汽或压缩气体流入泵内,排出液体。装在泵进口和出口的逆止阀,使液体在逆止阀的通路方向上流动。

Basic principle

The condensate control pump belongs to a pressure control pump and is mainly designed for situations where electricity is not applied to pump condensate or other fluids. Compared with the traditional water pump, the condensate control pump is especially suitable for the "difficult" medium, such as high temperature condensate water or corrosive fluid. Pressure operated pumps, especially condensate control pumps, are recognized as long - lived, rarely - maintained pumps. Because the pump has no rotary seal structure, no motor and pump impeller, the service life is usually five to ten times of the traditional electric pump, and at the same time, most of the general maintenance is omitted.

1, the high temperature condensate is sent back to the boiler, the chemical treatment agent of boiler water supply is saved, and the cost of reheating the feed water of the manufacturing material boiler is reduced.

2, the pump does not need electrical maintenance.

3, the pump can be safely used in dangerous or explosive environments.

4. According to the different models, the steam, compressed air or other gas can be controlled by the pressure of 0.5 to 1.6Mpa.

5. The maximum amount of water thinning up to 22000Kg/h.

The condensate control pump is discharged from the steam or compressed gas. The floating ball is connected to the connecting rod and the spring, and the intake valve and the exhaust valve are also driven. In the liquid filling cycle, the intake valve is closed and the exhaust valve opens, so that the condensate is filled into the pump body. When the floating ball rises with the level of the liquid level to the point of its stroke, the switch control mechanism opens the spring, opens the intake valve, and closes the exhaust valve. Steam or compressed gas flow into the pump and discharge the liquid. A reverse check valve is installed at the inlet and outlet of the pump to make the liquid flow in the direction of the reverse check valve.

表1—泵输疏能力(Kg/hr)table 1—pump capacity of infusion (kg/hr)

|

操作压力 (bar) Operation pressure |

总背压 (bar) Total backpressure |

不锈钢止逆阀Stainless steel check valve |

||||

|

1”×1” |

1-1/2”×1-1/2” |

2”×2” |

3”×2” |

3”×2” 双联 Dual |

||

|

0.34 |

0.14 |

1877 |

3455 |

5340 |

6264 |

12528 |

|

0.69 |

0.34 |

1886 |

3161 |

4413 |

5039 |

10077 |

|

|

0.14 |

2550 |

4704 |

6600 |

8010 |

16019 |

|

1.72 |

1.03 |

1795 |

2747 |

3480 |

3870 |

7739 |

|

|

0.69 |

2202 |

3534 |

4460 |

5088 |

10175 |

|

|

0.34 |

2648 |

4766 |

6255 |

7527 |

15054 |

|

3.45 |

2.76 |

1301 |

1873 |

2351 |

2535 |

5071 |

|

|

1.72 |

1974 |

2903 |

3456 |

3828 |

7655 |

|

|

0.69 |

2132 |

4194 |

5678 |

6699 |

13397 |

|

5.17 |

4.14 |

1266 |

1756 |

2146 |

2299 |

4597 |

|

|

2.76 |

1854 |

2601 |

3025 |

3306 |

6612 |

|

|

1.03 |

1758 |

3626 |

5453 |

6381 |

12762 |

|

6.90 |

5.52 |

1235 |

1673 |

2013 |

2146 |

4292 |

|

|

4.14 |

1642 |

2224 |

2564 |

2769 |

5538 |

|

|

2.76 |

2077 |

3001 |

3365 |

3711 |

7422 |

|

|

1.03 |

1255 |

29.6 |

5404 |

6472 |

12946 |

|

8.62 |

7.93 |

887 |

1353 |

1631 |

1722 |

3444 |

|

|

6.90 |

1207 |

1611 |

1916 |

2037 |

4075 |

|

|

5.52 |

1512 |

2007 |

2302 |

2469 |

4938 |

|

|

4.14 |

1848 |

2506 |

2827 |

3072 |

6144 |

|

|

2.76 |

1810 |

3271 |

3620 |

4016 |

8033 |

|

|

1.72 |

11337 |

3064 |

4869 |

5608 |

11215 |

|

10.34 |

8.28 |

1212 |

1601 |

1889 |

2004 |

4007 |

|

|

6.9 |

1440 |

1886 |

2156 |

2302 |

4604 |

|

|

5.52 |

1710 |

2261 |

2549 |

2745 |

5491 |

|

|

4.14 |

2029 |

2881 |

3180 |

3468 |

6936 |

|

|

2.76 |

1539 |

3217 |

3848 |

2023 |

8591 |

|

|

1.72 |

1052 |

2601 |

4716 |

5502 |

11005 |

表2—非蒸汽驱动气体疏液能力修正系数table 2—the correction coefficient of capacity of non steam driving gas infusion.

|

背压对驱动压力之比(BP:MP),% The ratio of backpressure to driving pressure |

||||||||

|

10% |

20% |

30% |

40% |

50% |

60% |

70% |

80% |

90% |

|

1.04 |

1.06 |

1.08 |

1.10 |

1.12 |

1.15 |

1.18 |

1.23 |

1.28 |

表3—可用充水压头对疏液能力的修正系数table 3—Correction coefficient of available pressure head of water charging on infusion capacity.

|

充水压头 (英寸) Water filled head (inch) |

止逆阀和管路尺寸(英寸)Check valve and pipeline size |

||||

|

1” |

1-1/2” |

2” |

3”×2” |

4” |

|

|

6 |

0.70 |

0.70 |

0.70 |

0.84 |

- |

|

1 |

1.00 |

1.00 |

1.00 |

1.00 |

0.7 |

|

2 |

1.20 |

1.20 |

1.20 |

1.08 |

1.00 |

|

36 |

1.35 |

1.35 |

1.35 |

1.20 |

1.10 |

|

48 |

- |

- |

- |

- |

1.15 |

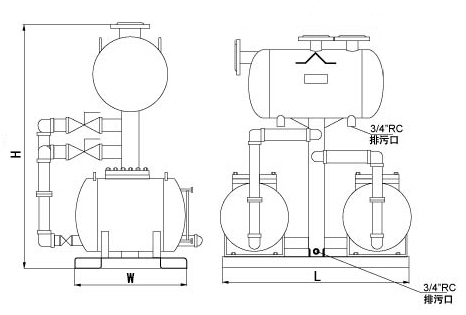

双联泵式凝结水回收装置 DOUBLE PUMP CONDENSED WATER RECOVERY DEVICE

外形尺寸/Prime out -form dimensions

|

型号 model |

尺寸 |

排水量 Drainage amount |

重量 Weight |

公称压力 (Mpa) Nominal pressure |

||

|

H |

W |

L |

||||

|

WDVSP2X5T |

1699.5 |

1740 |

1900 |

10T/h |

|

1.6 |

安装及启动操作

安装

1、凝结水控制泵的安装位置应保证其上游所有需排入该泵的凝结水均能顺利排入,建议进水压头为12”(305mm)并能够正确引入操作蒸汽或压缩空气。

2、在引入操作蒸汽时,其管路接口必须设在操作蒸汽主管道的上方,严禁设在主管道下方,以免主管道内的水、杂质等进入操作汽管路。

3、若凝结水控制泵用来回收多个疏水点排出的凝结水,考虑到不同疏水点排出的凝结水存在不同的余压,为防止不同疏水点间的相互干扰,建议在凝结水控制泵前安装集水罐,集水罐的尺寸确定见表。

4、凝结水控制泵的进出水口必须装有止回阀,以保证凝结水控制泵的正常运行。建议使用我公司提供的止回阀,以保证泵的排水量。

5、开式系统凝结水控制泵的安装建议见图。

6、凝结水控制泵需就位在承载能力大于其满罐时的总重量的地基上。地基表面需平整、干净。

7、在将凝结水进出管及操作气管接入凝结水控制泵之前必须将系统的管路吹扫干净,以免系统内的污物(如焊渣、铁锈等)进入凝结水控制泵,损坏泵体上的部件,影响泵的正常工作。

Installation and start operation

install

1, the installation location of condensate control pump should ensure that all upstream condensate discharged into the pump can be discharged smoothly, and the recommended inlet pressure head is 12 "(305mm), which can correctly introduce operation steam or compressed air.

2, in the operation of steam, above the pipeline interface must be located in the operation of a steam main pipe, is prohibited under the main pipe is arranged on the main pipeline, to avoid water and impurities into the operation of the steam pipe.

3, if the condensate pump control is used to recover the more hydrophobic point discharge condensate, taking into account the different hydrophobic point exhaust condensation water have different residual pressure, to prevent the mutual interference between different hydrophobic, suggested in the condensed water control pump installed before the water collecting tank, collecting tank size is opinion table.

4. The check valve must be installed in the inlet and outlet of the condensate control pump to ensure the normal operation of the condensate control pump. It is suggested that the check valve provided by our company should be used to ensure the drainage of the pump.

5. The installation of the condensate control pump for the open system is shown in the diagram.

6, the total weight of the water pump to control the setting in place carrying capacity is greater than the full of the ground. The surface of the foundation should be smooth and clean.

7, before condensing water enters and enters the condensate control pump, the pipeline of the system must be swept away, so as to avoid contaminants in the system, such as welding slag and rust, and enter the condensate control pump, which will damage the components of the pump body and affect the normal operation of the pump.

启 动

检查确定所有联接处都连接紧密后,开始试运行。

1.对于蒸汽操作场合,打开进汽口侧的疏水管线阀,将管内凝结水排空直至蒸汽出来后关闭该阀。

2.打开出水口阀及排汽口阀。

3.缓慢打开凝结水入口阀,向泵内充水,直至听到较为平缓的充水声后,将入口阀完全开启。

Start-up

Check and determine that all joints are connected tightly and start to run.

1. for steam operation occasions, drain pipeline valve to open the steam inlet side, the condensed water pipe emptying out after the valve is closed until the steam.

2. open the outlet valve and exhaust valve.

3. slowly open the condensate inlet valve, fill the pump with water until the more gentle sound of water filling, the entrance valve is completely opened.

常见故障排除Common troubleshooting

问题分析problem analysis

排除方法Elimination method

1. 结水在某水罐内积存,进不了泵内。

water is accumulated in a water tank and can not enter the pump.

a.进水阀未开water inlet valve closed

b.排气阀未开exhaust valve closed

c.罐内已充满水can be filled with water

d.进口止回阀未开inlet check valve open

a.打开进水阀Open the inlet valve

b.打开排汽阀Open exhaust valve

c.检查操作汽是否通入泵内,步骤同故障现象2的方法Check whether the operating steam is put into the pump, the method is the same as the failure phenomenon 2.

2.凝结水泵不排水Undrained condensate pump

a.操作汽未进到泵内Operating steam not into the pump

b.出口止回阀未打开Exit check valve unopened

c.泵内浮球机构未动作Floating ball mechanism in pump

a.检查动力汽是否供到泵处,检查泵的进汽口是否被污物堵塞Check whether the power steam is supplied to the pump and check whether the inlet of the pump is blocked by dirt

b.打开泵盖,看浮球是否上下动作自如,并将进、排汽阀切换打开,关闭,排除动作阻碍因素Open the lid of the pump to see if the floating ball moves freely and up and down, and switches the inlet and exhaust valves to open, close, and exclude the impediments of the movement.

c.将出口口止回阀打开,察看其动作情况,去除污等,使其动作无障碍Open the exit check valve, look at its action, remove pollution and so on, so that the action is no obstacle.

中文

中文 English

English