产品介绍:

单阀座:需要克服介质压力对阀座的作用,阀座的孔径不能很大,适用于小型设备、伴热管线,蒸汽主管等排水小的场合。阀座孔设计在凝结水水位以下,自然形成水封,水、汽自然分离,达到无蒸汽泄漏,即便没有凝结水采用球型密封的杠杆使得阀瓣紧贴阀座,达到无新鲜蒸汽的泄露。不受凝结水量波动和温度的影响。

双平衡阀座:该阀利用双阀孔设计,介质的压力对两个阀座作用相等,方向相反,介质压力对阀座作用相抵消,阀蕊在开阀时压力相对减少,从而获得超大排量。工作时浮球随阀腔内液体位的变化而上下浮动,带动杠杆打开或关闭阀座。由于阀座孔在凝结水水位以下,形成水封,水、汽自然分离,达到无蒸汽泄漏。不受压力、温度、冷凝水流量波动的影响。

Lever-ball float trap

Lever ball float type trap employs the buoyancy principle and the lever principles:to make the ball float ascend or descend by the change in the liquid level and then the ball float drives the lever to make the valve disc from or touch the valve seat to realize drainage and closed block vapor. The product adopts the automatic air exhaust to automatically eliminate non-condensing air.It is very precise with high operating and long service life.It can discharge whenever there is any water,and its minimum subcooled temperature is 0℃.The lever-ball float trap adopts two kinds of structure modes:A:Single valve seat-lever ball float;B:double balanced valve seat-lever ball float.

Single valve seat:it needs to overcome the operation on the valve seat by the medium pressure;the hole caliber of the valve seat cannot be too large and is applicable to such low displacement condition as mini-equipment,steam tracing pipeline and steam main pipe.The hole of the valve seat is designed beneath the water level of the condensate water to form water sealing to keep water apart from vapor,so as to prevent the leakage of the vapor.Though there is no condensate water that uses ball-type sealed lever to make the valve clack tightly adhesion to the valve seat,it can prevent the fresh vapor from leakage.Further,the product is free of the affect of the fluctuation of the condensate water's quantity and temperature.

The double balanced valve seat:this valve is designed to have two valve openings.The pressure of the medium act against the two valve seats equally in reverse direction,so the pressure on the valve seat is offset,the valve core assumes relatively low pressure when the valve is open,in this way the overlarge displacement is obtained.During the operating process,the ball float floats with the change in liquid level of the valve cavity to make the lever open or close the valve seat.The hole of the valve seat is designed beneath the water level of the condensate water to form water sealing to keep water apart from vapor,so as to prevent the leakage of the vapor.Further,the product is free of the affect caused by the fluctuation of pressure,temperature and condensate's flow.

优点:

1、采用新型阀机构(新 SCCV 关闭方式和Z型结构),具有优良的密封性和耐久性。2、双平衡阀座设计,比一般的疏水阀体积小而排量大,在特大排量场合更能发挥优越性。

3、单阀座设计可以水平或垂直安装,可以满足高背压,低排量蒸汽管线。

4、内装空气自动排放阀,可防止空气气堵和蒸汽汽锁。

5、全部部件安装在阀盖上,阀无需从配管上卸下,就可维修保养,简单方便。

Merits

1.To use new-style valve mechanism (new SCCV closing mode and Z-shaped structure) to boast excellent tightness and endurance.2.To employ double balanced valve seat design,it has smaller volume and larger displacement and can exert its advantages when needing large displacement.

3.The single valve seat model can be installed horizontally and vertically,satisfying the requirements of steam pipeline with high backpressure and low displacement.

4.The built-in automatic air exhaust can prevent air blocking and steam locking;

5.As all components are installed on the valve cover,so they can be maintained and cleaned up simply and easily without being removed from pipe arrangement.

热静力浮球式疏水阀/THERMAL-STATIC-BALL FLOAT TRAP

技术参数/Technique parameter

|

壳体压力等级 Shell pressure grade |

负荷泄漏率 Load leakage |

使用介质 Used medium |

允许背压率 Permitted Backpressure rate |

节能效果 Energy Saving effect |

最大工作压差 Maximum operating pressure differential |

|

1.6、2.5、4.0、10MPA |

≈0% |

蒸汽、凝结水 Steam、Condensate water |

≥90% |

优秀/良好 Excellence/good |

10MPA |

|

最小过冷度 Minimum Subcooled temperature |

排水方式 Drainage method |

最高允许温度 Maximum allowable temperature |

排空气装置 Air exhaust system |

压力变化范围 Pressure change range |

|

|

0℃ |

连续方式 Continue mode |

420℃ |

自动 Automatic |

适应 Adaption |

|

主要零件材料/The materials of primary accessories

零部件名称Part and component name

材质Material

阀体、阀盖Valve body、Valve cover

铸钢、不锈钢Cast steel、Stainless steel

浮球、杠杆Float ball、Lever

304不锈钢304 Stainless steel

双平衡阀座Dual Balance valve seat

STL合金和不锈钢组合Combination of STL alloy and Stainless steel

自动排空气装置Automatic air exhaust

不锈钢、热敏元件Stainless steel、Thermo-sensitive element

过滤网Filtrating screen

不锈钢Stainless steel

外形尺寸和重量/Prime out-form dimensions and weigh

|

产品型号 Product model |

口径(DN) Calibre |

L法兰 Flange |

L螺纹/焊接 Thread/welding |

H1 |

H2 |

W |

重量(kg) weight |

使用压力范围(MPa) Pressure Change range |

公称压力(MPa) Nominal pressure |

|

FQ21 |

15-25 |

- |

170 |

74 |

74 |

148 |

7 |

0.1-2.5 |

2.5 |

|

FQ24 |

15-50 |

230 |

- |

74 |

74 |

148 |

9-13 |

0.1-2.5 |

2.5 |

|

FQ21-40 |

15-25 |

- |

200 |

85 |

85 |

170 |

8 |

0.1-3.2 |

4.0 |

|

FQ24-40 |

15-25 |

300 |

- |

85 |

85 |

170 |

12 |

0.1-3.2 |

4.0 |

注解:

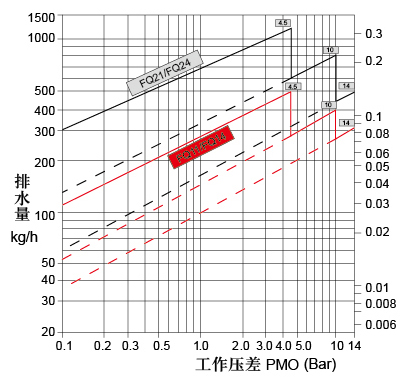

1、选型时请提供工作压力、工作压差、凝结水发生量、工作温度、连接方式及标准。

2、双平衡阀座凝结水负荷的安全系数一般为1.5~2倍,单阀座凝结水负荷的安全系数为3。

3、正确安装、定期保养清除阀内污物,保证疏水阀正常工作和延长使用寿命。

Note

1.Please provide operating pressure and operating pressure difference,generating quantity of condensate water,operating temperature,connecting mode and standards in selecting product models.

2.The safely coefficient for condensate water load of dual balance valve seat is generally 1.5 to 2 times,and the safely coefficient for condensate water load of single valve seat is 3 times.

3.Please make sure the drain valve is installed properly,maintained regularly,cleaned up and operates under the normal condition,so as to extend its service life.

中文

中文 English

English