产品介绍:

环工作,间断排水

倒吊桶式蒸汽疏水阀是机械型蒸汽疏水阀中坚固的疏水阀之一,它的优点是:不怕水击,能连续排不冷凝气体,抗污性能好;最高背压≥90%,所有内件都是不锈钢制造,耐磨损、抗腐蚀;球形阀心和阀座是线接触,密封性能好,使用寿命长;间断排水和连续排水,能排接近饱和温度冷凝水,使加热设备达到理想工作效率。倒吊桶式蒸汽疏水阀的阀座处于水密封的保护下,工作时无活蒸汽泄漏,节能效果好。

它适用于石油、化工、印刷、造纸、制药等工业蒸汽加热设备和蒸汽管网的阻汽排水。

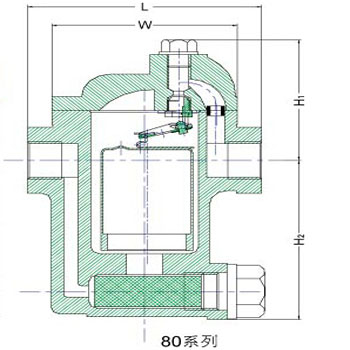

Inverted Bucket Trap

The interior of the inverted bucket steam trap:this valve adopts the operating principles of density difference between condensate water and steam,and the leverage system connects with inverted bucket to form its internal structure,thus controlling the open and close of the steam pressure.The interior of the inverted bucket steam trap is an inverted bucket,a liquid level sensitive part,with the bucket's opening downward.When the device just started,air and low temperature condensate water occur in the pipes,at the moment the steam trap opens thoroughly,the air and low-temperature condensate water are discharged rapidly and the temperature of the device rises immediately.When any steam enters into the inverted bucket,the bucket will obtain buoyancy and the fixed lever of the bucket drives the valve core to close the valve.There is small aperture on the inverted bucket,which can discharge air automatically.As some of steam is discharged from such aperture,while other steam produces condensate water.The inverted bucket loses the buoyancy and sinks down and its fixed lever drives the valve core to open the valve.When the steam re-enters into the bucket,the valve will close again.It repeats the said procedures to discharge water intermittently.The inverted bucket steam trap is one of the most solid mechanical steam traps. It has the following advantages: it is not afraid of water hammer, can continuously discharge non condensing gas, and has good anti pollution performance; the maximum back pressure is ≥ 90%, all internal parts are made of stainless steel, wear-resistant and anti-corrosion; the ball valve core and valve seat are in line contact, with good sealing performance and long service life; intermittent drainage and continuous drainage It can discharge condensate close to saturation temperature and make heating equipment reach ideal working efficiency. The valve seat of inverted bucket steam trap is under the protection of water seal, and there is no live steam leakage during operation, so the effect of energy saving is good.

The product applies to such industrial steam heating equipment as petroleum,chemical,printing,paper making and pharmaceuticals and discharge of the steam pipe network.

优点:

1、内腔所有运动部件均为不锈钢,耐磨损,耐腐蚀。2、由于蒸汽不能到达被水封的阀座孔,所以无蒸汽损失,高效节能。

3、浮桶倒置,不会被破坏压扁,不怕水击,寿命长。

4、倒置桶顶部设有排气孔。连续排空气性能好,不会形成冷滞后和气堵。

5、不受背压的影响,在高的背压下能很好地工作。

6、工作可靠,只有两个运动部件 ( 自由杠杆结构和倒置桶 ) ,故不会产生卡阻。

7、阀座与阀瓣在阀的顶部,阀瓣在开关中可以使污物通过,有良好的自我清洗性能 ,无污物困扰。

Merits

1.All moving parts of the internal cavity are made of stainless steel,capable of resistance to abrasion and erosion.2.As the steam cannot reach the sealed aperture of the valve seat by water,the steam will not lose but has high efficiency and save energy.

3.The float bucket is located inversely.It can resist to water's strike and has long service lift.

4.The invented bucket has gas vent and performance of discharging the air continuously is excellent,without forming cool hysteresis and air blocking.

5.It is free of the affect of the back pressure and can perform well under high back pressure.

6.It has reliable operation and only two moving parts—free lever structure and inverted bucket,so no blockage is produced.

7.The valve seat and valve disc are located at the top of the valve.The valve disc allows the pollutants to pass,so it attains good self-cleaning performance,without affected by pollutants.

主要特点

1、对凝结水的发生量适应性强,既可间歇排放,又可连续排放。

2、汽水分离可靠,阀内始终处于水封状态,有效阻止蒸汽泄露。

3、敞口型的浮子抗水击,设有排水孔,防止气锁或气堵现象。

4、用于蒸汽主管、分气缸、热交换器、硫化机、干燥机、空调机、医院用汽设备等。

Main Features

1.Have strong adaptive capacity to the occurrence quantity of condensation water,namely,the ability to both intermittent and continuous discharge.

2.Reliable separation of steam and water,the inner part of the valve is always in water seal state,which can effectively prevent the leakage of steam.

3.Open mouth-shaped float resists water attack,and is equipped with a vent so as to prevent vapor lock or gas block.

4.Mainly used in the steam main pipe,sub-cylinder,heat exchanger,vulcanizing machine,dryer,air-conditioning machine,hospital steam equipment,etc.

倒吊桶式疏水阀/INVERTED BUCKET TRAP

技术参数/Technique parameter

|

壳体压力等级 Shell Pressure grade |

负荷泄漏率 Load leakage |

使用介质 Used medium |

排出高温气体 Discharging of high- temperature air |

允许背压率 Permitted backpressure rate |

节能效果 Energy saving effect |

|

1.6、 2.5、 4.0MPA |

≈0% |

蒸汽、凝结水 Steam、 Condensate water |

适应 Adaption |

≥90% |

优秀/ 良好 Excellence/ good |

|

处理污物 Disposal Of feculence |

最大工作压差 Maximum operating Pressure differential |

排水方式 Drainage method |

最高允许温度 Maximum allowable temperature |

排空气装置 Air exhaust system |

抗水击 Resist |

|

适应 Adaption |

4.0MPA |

连续方式 Continue mode |

420℃ |

自动 Automatic |

适应 Adaption |

|

零部件名称 Part and component name |

材质 Material |

|

阀体、阀盖 Valve body、Valve cover |

铸钢、不锈钢 、合金钢 Cast steel、Stainless steel、Alloy steel |

|

吊桶、杠杆 Inverted bucket、Lever |

304/316不锈钢 304/316 Stainless steel |

|

阀座、阀瓣 Valve seat、Valve clack |

STL合金、高铬不锈钢 STLAlloy、High chrome stainless steel |

|

自动排空气装置 Automatic air exhaust |

不锈钢、热敏元件 Stainless steel、Thermo-sensitive element |

|

过滤网 Filtrating screen |

不锈钢 Stainless steel |

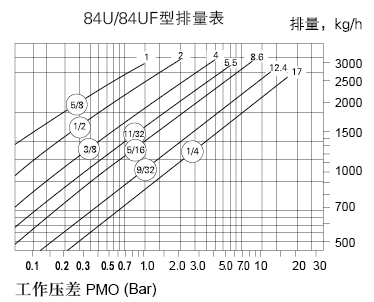

外形尺寸和重量/Prime out-form dimensions and weigh

|

产品型号 Product model |

口径(DN) Calibre |

L法兰 Flange |

L螺纹/焊接 Thread/welding |

H1 |

H2 |

W |

重量(kg) weight |

使用压力范围(MPa) Pressure change range |

公称压力(MPa) Nominal pressure |

|

84U 84UF |

25 32-40 50 |

310 320 330 |

245 |

152 |

246 |

205 |

25 28 30 |

0.1-2.5·3.2 |

2.5-4.0 |

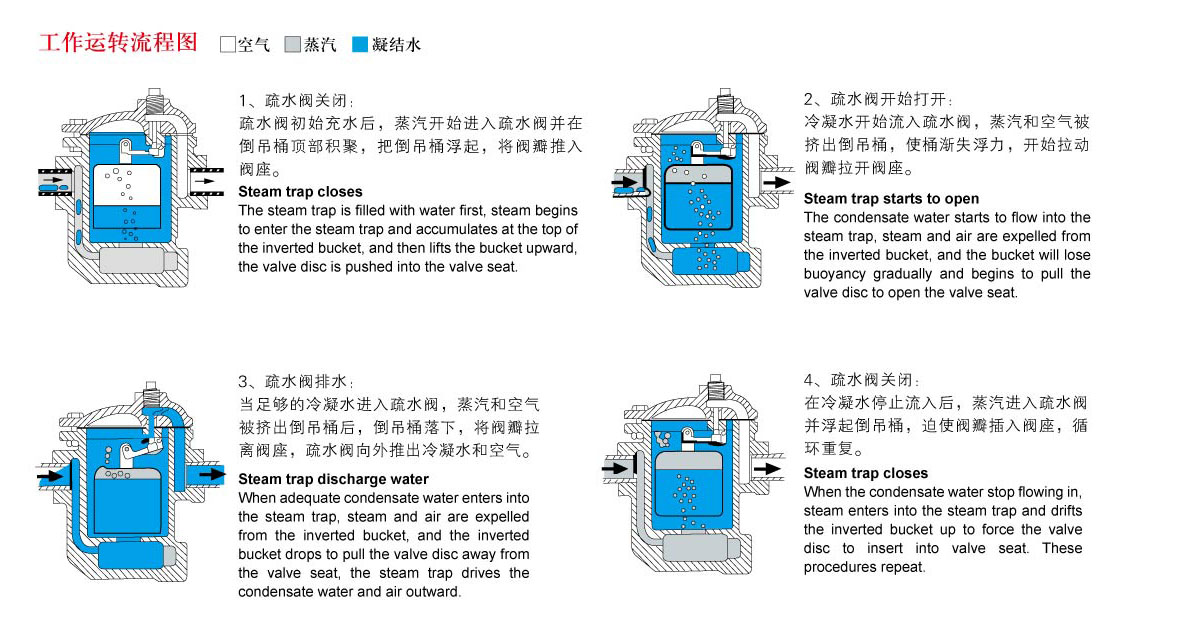

排水量/Capacity

注解:

1、选型时请提供工作压力、工作压差、凝结水发生量、工作温度、连接方式及标准。

2、凝结水负荷的安全系数一般为2~3倍

3、正确安装、定期保养清除阀内污物,保证疏水阀正常工作和延长使用寿命。

4、型号尾数数值相同,其排水量也相同。

Note

1.Please provide operating pressure and operating pressure difference,generating quantity of condensate water,operating temperature,connecting mode and standards in selecting product models.

2.The load of condensate water’s safety coefficient reaches 2 to 3 times in general.

3.Please make sure the drain valve is installed properly,maintained regularly,cleaned up and operates under the normal condition,so as to extend its service life.

4.The products with same mantissa figure at their models have the same discharge capacity.

中文

中文 English

English